Thermographic

Inspection

Thanks to the further development of drones and cameras, a thermographic inspections of existing solar installations has established itself as an effective method of analysis.

About

Thermographic Inspection

Thermography

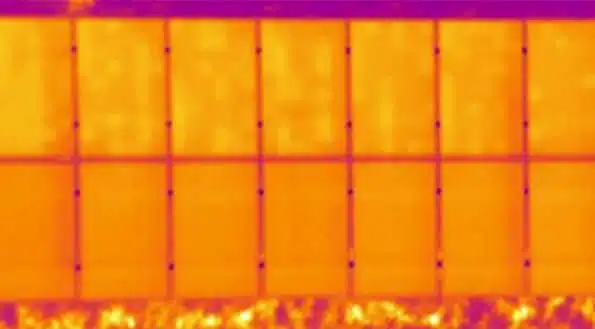

Infrared images visualise faults that are hardly detectable visually and very difficult to measure from a technical point of view. For PV systems, this inspection technique provides valuable information, regarding the technical condition of the system, and faults that are relevant in terms of performance and safety.

We offer you a flexible full-service package for your photovoltaic plant, which you can put together in modules, depending on your wishes and the technical specifications of your PV plant.

We observe the relevant standards strictly in order to achieve reliable results and generate a basis for subsequent warranty processes or necessary repairs.

When does an

thermographic

inspection makes sense?

If you have noticed a decrease in the power generation of your plant or if you want to check your modules

This process provides you with a detailed report that allows you to identify defective modules and their specific location, which simplifies the maintenance and repair process.

Additionally, this inspection helps to increase the efficiency and lifespan of your photovoltaic modules, as it can detect temperature differences and potential hot spots that could lead to permanent damage if not addressed in a timely manner.

If you want to recognize faults at an early stage and enhance the useful life of your modules

Additionally, with a thermographic PV evaluation, you can detect potential hotspots and module damage caused by environmental factors, such as hail or lightning strikes, and take corrective measures to prevent further damage. This can help extend the lifespan of your PV system and optimize its performance, resulting in a better return on investment.

If you are planning to acquire a PV plant and want to check the condition of the modules

Our team of experts uses high-resolution thermographic cameras, mounted on drones, to capture aerial images of your photovoltaic modules. These images are then processed using advanced software, which detects thermal anomalies and assigns them to specific modules. This helps to pinpoint any potential issues with your system and allows for a more accurate diagnosis and repair plan. The results of the thermographic inspection are presented to you in an easy-to-understand report, complete with recommendations for corrective action.

If you need information for the sale of your plant

For sellers, our inspection services offer an opportunity to proactively address any issues identified through thermographic analysis. By ordering targeted repairs and documenting them before the sale, sellers can demonstrate the quality and reliability of their solar power plant, potentially leading to a better overall purchase price.

Our team of certified thermographic experts uses state-of-the-art drone technology and advanced software to provide you with accurate and reliable results. We understand the importance of thermographic evaluation in assessing the performance and safety of your photovoltaic system, and our services are designed to help you make informed decisions in the buying or selling process.

If one of the warranties from your contractor or module manufacturer is about to expire

Adhering to relevant standards is critical to ensuring the accuracy and reliability of the results of our inspections. Our team of experts follows strict guidelines and industry standards, such as the International Electrotechnical Commission (IEC) 62446, to ensure that our inspections are carried out to the highest level of quality. This approach allows us to generate reliable and trustworthy results that can be used as a basis for any warranty processes or necessary repairs.

Contact

Talk to our specialists at greentech about your needs in terms of Thermographic Inspection.

Anomalies and error patterns that can be detected with thermography

Cell damage and hotspots

Defective cell strings

Potential-induced degradation

What makes our thermographic inspection stand out in the crowd?

Full-service package, especially suitable for large projects

An interdisciplinary team of experts

A comprehensive analysis with evaluation and suggested solutions

Discover our full range of services for the thermographic inspection of your plant

Thermographic images

Analysis and technical solution concept

Why work with greentech?

Years of experience

Projects

Professionals in our team

under management

About greentech

With advice and action at your side - in every phase of your project

greentech is an integrated PV specialist. The range of services includes project development, system design, construction, operation and management of PV power plants in Europe. In the area of operational management, we offer a full-service operational management concept for PV plants of all sizes with an interdisciplinary team of experienced experts, as well as services for planning, quality assurance and yield maximisation. With a comprehensive range of services and a current portfolio of more than 1 GWp in operational management, we are one of the largest independent service providers worldwide. As an integrated PV specialist, greentech also covers the areas of project development and plant construction.

Your greentech specialists for

thermography

Johannes Liebich

Head of Engineering & Technical Advisory

Steffen Heberlein

Senior Project Manager Sales & Business Development