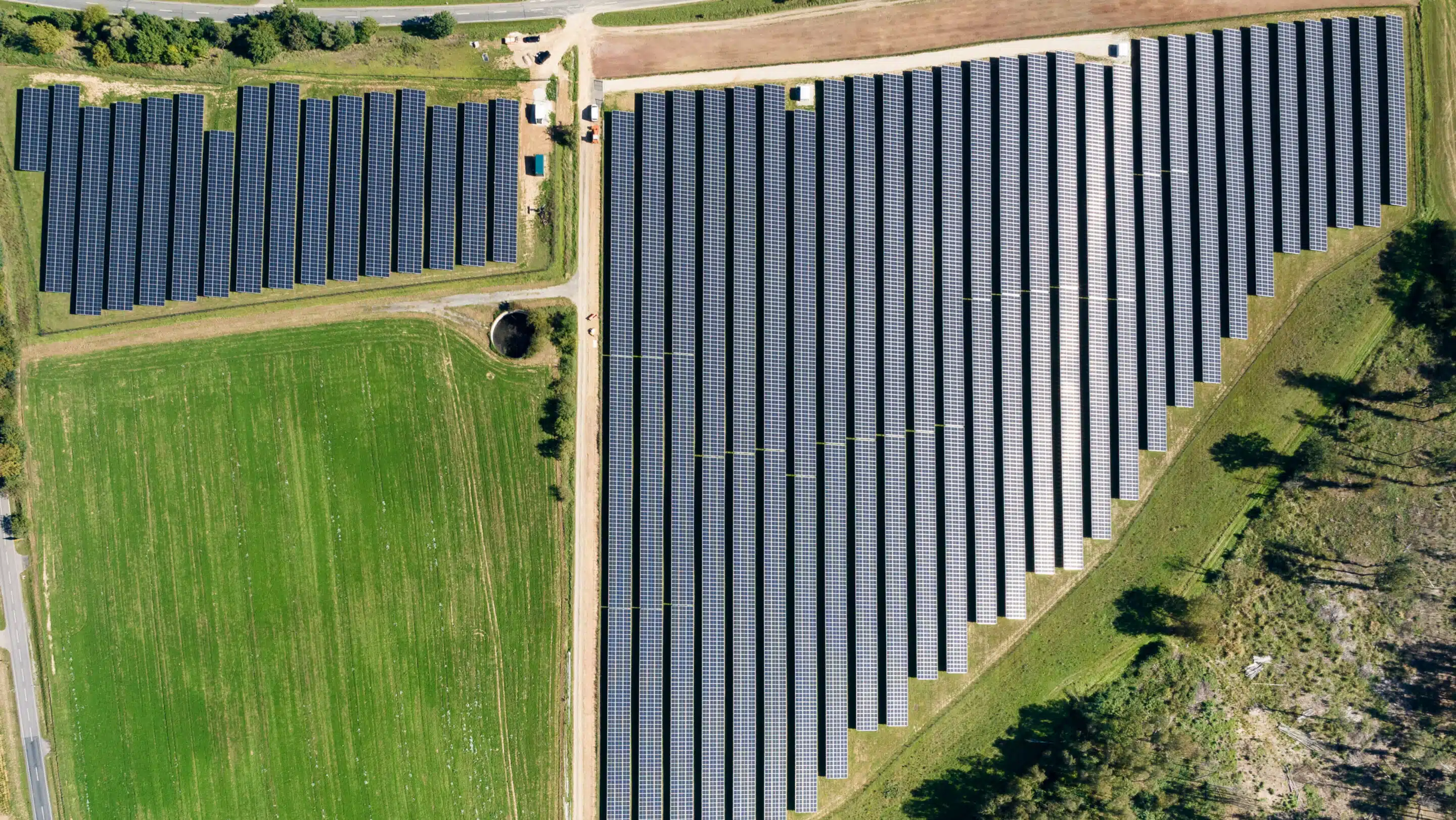

Developing, designing, building and operating solar power plants.

This is how we engage for a life-friendly future, powered by green energy.

With a team of around 200 employees, greentech is a leading expert in project development, plant design, technical consulting, construction, operational management and asset management of photovoltaic power plants.

As a fully integrated PV specialist, we cover the entire value chain in realising PV power plants. Our focus: to advance the urgently needed expansion of renewable energies, to operate power plants reliably and optimally, and to manage assets successfully. In this way, we make a measurable long-term contribution to the complete switch to green energy.

Business Areas

Years of experience

Projects

Professionals in our team

under management

News-Highlights

We strive to make the world a greener and better place, here is how:

greentech enters the Irish photovoltaic market with operations & maintenance services

Hamburg, 08.04.2024 – The photovoltaic expert greentech officially entered the Irish PV market as of March 2024 with founding the local entity greentech solar services Limited, based in Dublin. "We are impressed by the dynamic nature of the Irish PV market - it offers...

greentech joins Solar Stewardship Initiative by SolarPower Europe and Solar Energy UK

Hamburg, 01.03.2024 – greentech has joined the Solar Stewardship Initiative (SSI), recently launched by SolarPower Europe and Solar Energy UK, as part of its ESG strategy and with the aim of ensuring and sustainably promoting social and environmental standards in the...

Irland Markteintritt

“We are impressed by the dynamic nature of the Irish PV market – it offers great potential for us. We are well positioned to offer our range of services and can utilise our experience and service quality as an established expert in the European solar market,” states Jörn Carstensen, CTO at greentech.

Find the whole press release on our website: https://lnkd.in/e-ZGwsqP

#greentech #photovoltaics #ireland

Idstein: Ramming work in progress

The construction works recently started on our latest project in Idstein. We are currently building a plant with a zize of 7.5 MWp on a privileged site next to the A3 motorway. Commissioning is planned for end of May.

#greentech #pv #photovoltaics

Construction start in Meschede

The ramming machine is running: This week we started construction of a 7.5 MWp plant in Meschede, NRW. The project was developed by Blue Elephant Energy GmbH and we are pleased to take over as #EPC.

We are working on this construction site with modules from Canadian Solar Inc., SMA Solar Technology AG central inverter and CWF GmbH Mounting Structure.

Commissioning is planned for June.

#greentech #pvconstruction

greentech Careers

You want to combine your profession with a meaningful goal?

At greentech we work together and with passion on our mission to make electricity from renewable energies a matter of course. We are happy to welcome new, committed colleagues who want to make a difference together as a team and with new ideas!

Take a look at our job portal. – Haven’t found a suitable position? Then send us an open application!

Contact